|

FlowLab™

Low cost, entry level, 2 channel flow chemistry system

- 2 High pressure pumps with integrated pressure transducers

- HotCoil™ heated coil reactor station

- FlowLab™ automated system control software with data logging

- Wi-Fi remote control

- Quickly save and reload experiments

- Supplied with 5.0ml stainless and 5.0ml PTFE coil reactors and back pressure regulator

FlowLab™ is an affordable and easy-to-use entry level flow chemistry system that is ideal for education, training

and for those wishing to try flow chemistry without the associated costs of a sophisticated fully automatic system.

The system comprises of 2 high pressure pumps, a HotCoil™ coil reactor station and FlowLab system control

software. A 5ml PTFE and a 5ml 316L stainless steel coil reactor and a fixed back pressure regulator (BPR) are

included. The computer, pumps and HotCoil are connected over a LAN using an Ethernet HUB. In this way, the

system can be operated remotely by Wi-Fi allowing the control computer to be conveniently positioned outside the

fume cupboard and away from chemicals.

Optionally available, as shown above, are a stand and 4 position manual PTFE inlet valves for each pump.

The pumps have a combined flow rate range of 0.01 to 20 ml/min and will operate up to 100 bar (200bar is

available as an opti�on). Each pump has a built in pressure transducer and safe operating pressure limits can be set

by the user. The reagents are mixed at a “T”-piece and then flow through the coil reactor and into a collection

botlle. Back pressure is set by a fixed back pressure regulator cartridge positioned in-line with the flow stream.

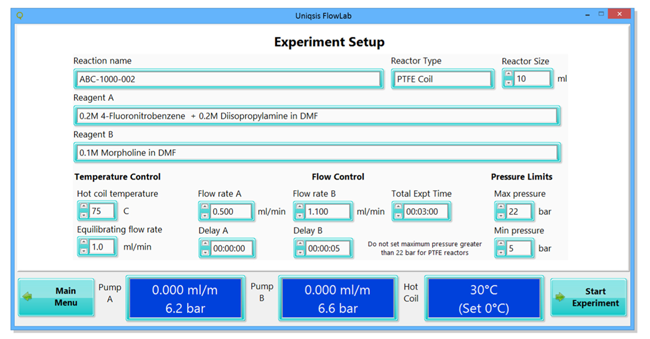

The FlowLab application affords control of the system via a ‘step-through’ interface that is straighforward to use.

Specific control screens allow users to modify system settings and perform automated priming and wash functions

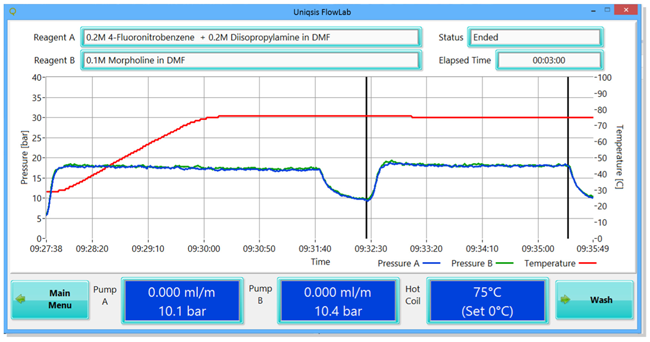

in addition to designing new, or loading previous, experiments. Reactions can be run automatically on a time basis,

and reaction progress is monitored in real-time from a plot of temperature and pressures. The reagents used can

be entered in text fields and logged data is automatically saved.

For operational safety, FlowLab software monitors pressure and temperature and will automatically shut down if

there is a blockage, leakage or overheating.

Straighforward experiment setup ...

Real-�time monitoring of temperatures and pressures ...

UQ1026 Uniqsis FlowLab™ system comprises:

Pumps: HPLC pumps with pressure transducers; 0.01 to 10.0 ml/min, Pmax =100bar (2 each)

Reactor module: HotCoil reactor station ambient to 260°C (300°C option)

Coil reactors: 5.0ml stainless steel and 5.0ml coil reactors (1 each),

Computer: Laptop with FlowLab control application installed

Accessories: PTFE “T”-piece mixer and connecting tubing

100psi Fixed back pressure regulator and PEEK holder

Botlles and caps

Ethernet Hub and Wi-Fi router

Uniqsis FlowLab™ optional extras:

A wide range of op�tional accessories are compa�tible with FlowLab. These include coil reactors in sizes ranging from 2.0ml to 60ml constructed of PTFE, PFA, 316L stainless steel, Hastelloy® or copper tubing.

A selec�tion of standard (PEEK) or chemically inert (Hastelloy® and

perfluoropolymer) in-line back pressure regulator cartridges (5-50bar).

The HotCoil coil reactor can be fitted with the HotColumn™ accessory (shown opposite). This can accommodate up to 6 column reactors for catalyti�c or scavenging applica�tions and holders that fit different sized columns can be specified. |

|

| |

All system components are CE marked and are covered by a 12 month warranty against component malfunction

and defective workmanship.

|

|